Automatic Snack Packaging Film Roll: Reliable OEM Packaging Solution for U.S. Food Brands

Introduction to Automatic Snack Packaging Film Roll

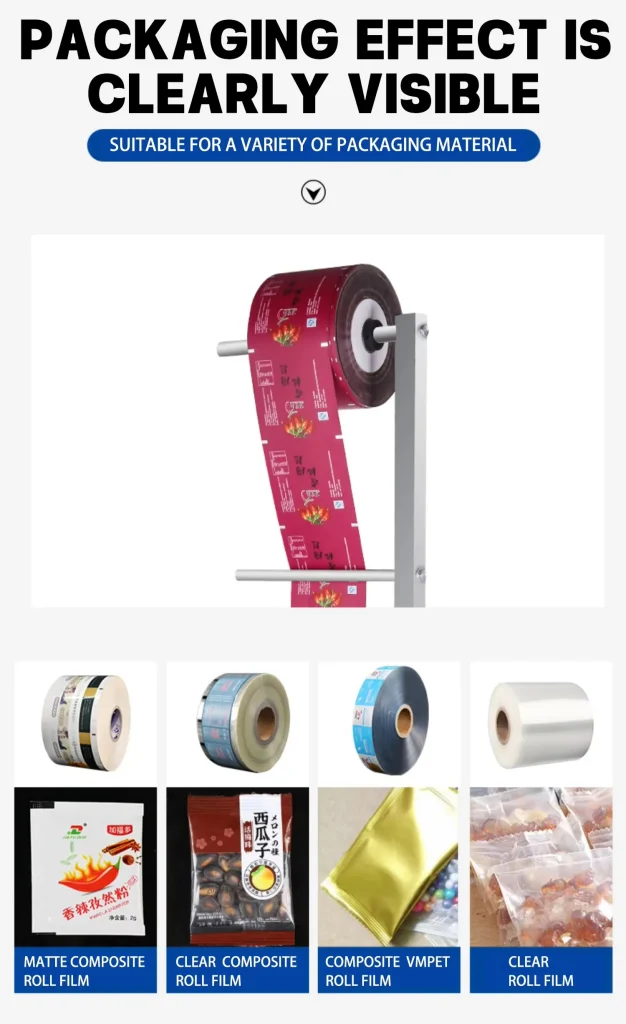

In the competitive U.S. snack industry, packaging quality directly influences shelf life, product presentation, and consumer satisfaction. Our automatic snack packaging film roll is engineered for high-speed packaging machines and delivers exceptional barrier protection, sealing performance, and print precision.

At Flexible Packaging Factory, we manufacture custom-printed flexible packaging film rolls that meet international food safety standards (FDA, SGS, ISO). Designed for both vertical (VFFS) and horizontal (HFFS) form-fill-seal systems, these films are ideal for packaging snacks, cookies, candy, and coffee products.

This product is part of our OEM and ODM packaging solutions — offering brand owners in the United States complete customization with professional-grade printing, lamination, and sustainability options.

What Is an Automatic Snack Packaging Film Roll?

An automatic packaging film roll is a continuous laminated film designed to be used in automated food packaging lines. The film is heat-sealed to form pouches or sachets that protect snacks from air, moisture, and light exposure.

Our snack packaging rolls are made from multi-layer materials such as PET, BOPP, CPP, PE, and aluminum foil, ensuring a perfect balance of flexibility, strength, and durability.

Whether you’re packaging potato chips, candy, nuts, or protein snacks, our OEM film rolls ensure consistent machine performance and minimal downtime.

Key Features and Technical Advantages

Our automatic snack packaging film rolls are built for performance and precision. Every roll is optimized for U.S. market expectations in quality, compliance, and convenience.

Key technical features include:

-

Material Options: PET/PE, BOPP/CPP, PET/AL/PE, PET/Met BOPP/CPP

-

Thickness: 50–120 microns

-

Width: 100mm–1200mm

-

Printing: Up to 10 colors (rotogravure or digital)

-

Core Size: Standard 3-inch (customizable)

-

Surface Finish: Glossy, matte, or metallic

-

Certifications: FDA, SGS, ISO food safety compliant

Machine Compatibility: Suitable for automatic horizontal and vertical packaging machines (Bosch, Ilapak, Ishida, etc.), ensuring stable unwinding and high-speed performance.

Application of Automatic Snack Packaging Film Roll

The automatic snack packaging film roll can be used across multiple sectors in the food industry. Typical applications include:

-

Snack foods: Potato chips, popcorn, pretzels, trail mixes

-

Confectionery: Candy, chocolate, gummies

-

Baked goods: Cookies, biscuits, crackers

-

Coffee and tea: Instant coffee, ground coffee, tea sachets

-

Frozen and dry foods: Noodles, nuts, cereals, and ready-to-eat meals

Every application benefits from high oxygen and moisture barrier properties, ensuring long-lasting freshness and premium shelf presentation.

Material Structure and Barrier Performance

Our laminated films are made with high-performance materials that protect against oxygen, moisture, and UV damage — crucial for U.S. snack manufacturers aiming to maintain crispness and flavor.

Typical Structure Breakdown:

-

Outer Layer (PET or BOPP): Provides gloss, stiffness, and printability.

-

Middle Layer (Aluminum Foil or Met BOPP): Acts as a strong oxygen and light barrier.

-

Inner Layer (CPP or PE): Offers excellent heat sealing and food safety.

These materials are bonded through solvent-free lamination, guaranteeing food-safe, odorless, and eco-conscious packaging.

Advantages for U.S. Snack Manufacturers

Choosing the right automatic snack packaging film roll gives your brand a competitive edge in performance, efficiency, and sustainability.

Top benefits include:

-

Exceptional Barrier Protection: Maintains product freshness and crunchiness.

-

Custom OEM Printing: Vibrant, detailed designs up to 10 colors.

-

Machine-Friendly: Smooth, consistent roll tension for high-speed packaging lines.

-

Enhanced Shelf Appeal: Glossy, matte, or metallic finishes that attract consumers.

-

Food Safety Compliance: Manufactured with FDA-approved materials.

-

Sustainability Options: Recyclable and compostable film structures available.

-

Cost Efficiency: Reduced waste and longer roll life for automatic systems.

Our films are trusted by private-label brands, co-packers, and food factories across the United States.

Customization Options for OEM & ODM Orders

We provide full OEM and ODM customization services to help U.S. brands stand out on supermarket shelves.

Customization includes:

-

Brand logo and color matching

-

Matte or glossy finish combinations

-

Transparent or window sections

-

Custom roll dimensions

-

Zipper or resealable function integration

Each order is supported by our in-house design and engineering teams to ensure optimal packaging performance and brand consistency.

Sustainability and Eco-Friendly Choices

As the U.S. market increasingly emphasizes eco-conscious packaging, we offer sustainable flexible packaging film rolls made from recyclable PE or biodegradable PLA materials.

Our commitment to sustainability includes:

-

Solvent-free lamination processes

-

Lightweight film structures to reduce waste

-

Recyclable mono-material packaging options

These innovations help food brands meet environmental goals while maintaining barrier integrity and branding quality.

Why Choose Flexible Packaging Factory as Your OEM Supplier

Flexible Packaging Factory is an experienced manufacturer specializing in automatic snack packaging film rolls for global food producers. Our production facilities integrate high-speed printing, lamination, and slitting systems for consistent quality and fast turnaround.

Why U.S. buyers trust us:

-

Direct factory supply, competitive pricing

-

FDA-approved food-grade raw materials

-

Experienced OEM & ODM packaging support

-

Global export expertise (North America, Europe, Australia)

-

Quick lead times and reliable logistics

Our goal is to help snack brands streamline packaging operations while maintaining superior quality and efficiency.

How to Order Automatic Snack Packaging Film Rolls

Ordering OEM packaging film from us is simple:

-

Contact our team with your product type and roll specifications.

-

Choose materials and printing design (we can assist with artwork setup).

-

Approve digital proof before mass production.

-

Receive sample rolls for machine testing.

-

Mass production and worldwide shipping within the agreed timeframe.

You can Request a Quote online or email us directly for personalized assistance.

Contact Us

If you are looking for a reliable OEM automatic snack packaging film roll supplier for your U.S. snack or candy products, get in touch today for a free consultation or custom quote.

Email: info@flexiblepackagingfactory.com

WhatsApp: +86 186 319 51156